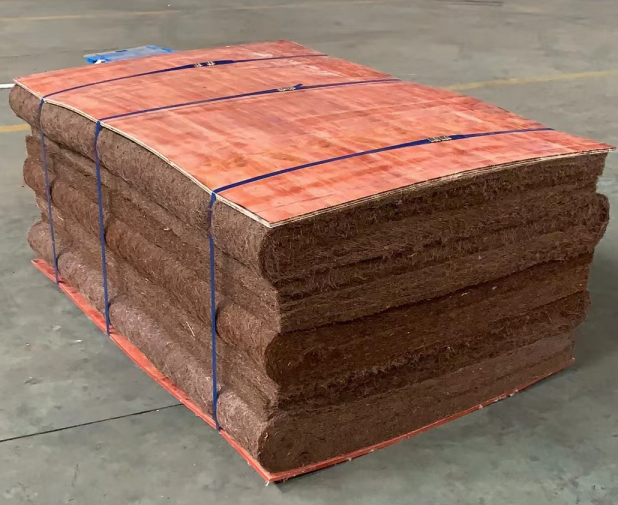

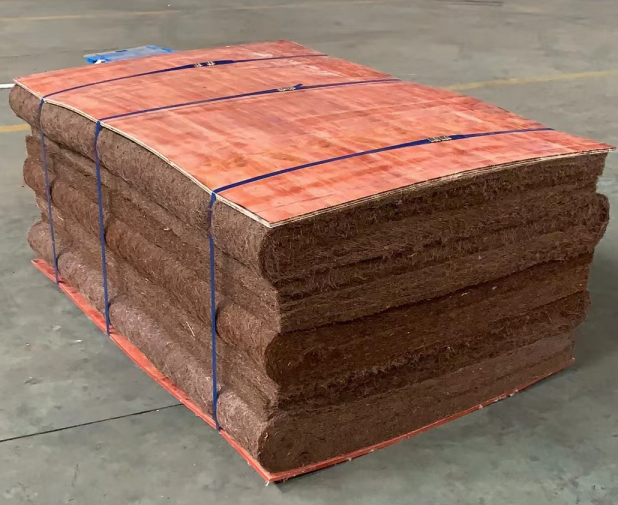

Coconut Mat for nitrogen generator

Coconut Mat for nitrogen generator

Sep .23.2022

Coconut mat made by natural coco coir is used for compacting and fixing of filler materials in industry equipment to make sure the equipment safe and reliable. And it could be used in nitrogen generator. Since Coconut mat has a charactoristic of good elastic,so it is used to produce coconut mat use to provent the pulverization of carbon molecular sieve in the process of nitrogen gas generation.

![Adsorption and its Applications in Industry and Environmental Protection]() Adsorption and its Applications in Industry and Environmental Protection

Adsorption and its Applications in Industry and Environmental Protection

Jul .09.2021

CMS have had a significant impact on separation processes and they have also found applications as catalysts. In recent years, most research and development efforts concerning CMS materials have been devoted to their preparation, property characterization and use in gas separations [4]. Less attention has been paid to their catalytic properties and their use as selective catalyst support, which is currently an active field of research [5, 6].

The measurement of preventing carbon molecular sieve from powdering in the nitrogen generator

The measurement of preventing carbon molecular sieve from powdering in the nitrogen generator

Jun .23.2021

The measurement of preventing carbon molecular sieve from powdering in the nitrogen generator

1. Choose the good quality carbon molecular sieve and good brand.

2. Make the reasonable layout. For example, we can lay the inert alumina and activated alumina first ,then lay the carbon molecular sieve. In this way, it not only distributes the airflow reasonably and prevents the impact, but also reach the goal of purification.

3. Install the filling bed firmly and neatly.

4. Design the reasonable use pressure and regeneration time.

The production of nitrogen

The production of nitrogen

Jun .15.2019

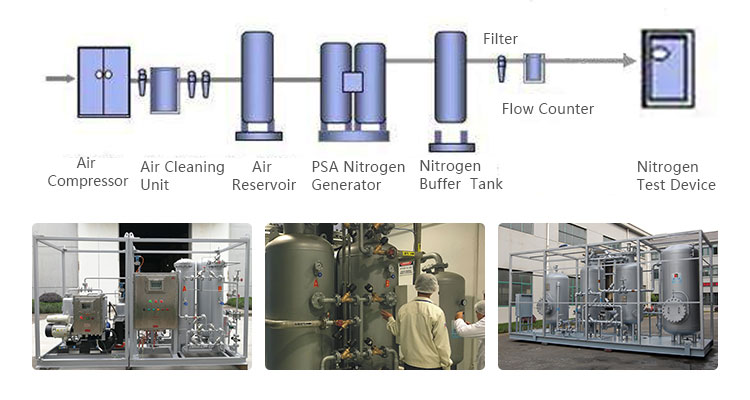

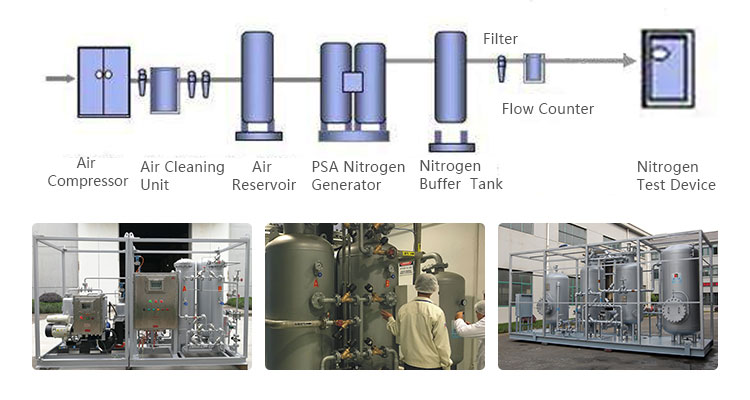

Carbon molecular sieve is the adsorbent on PSA nitrogen production device. Nitrogen is prepared from the air by PSA.The separation of oxygen and nitrogen in the air is mainly based on the different diffusion rates of the two gases on the surface of the carbon molecular sieve.The diffusion rate of gas molecules (O2) with smaller diameter is faster, and more of them enter the carbon molecular sieve micropores. The larger diameter gas molecule (N2) diffuses at a slower rate and enters fewer pores in the carbon molecular sieve, so that nitrogen enrichment can be obtained in the gas phase.

Coconut Mat for nitrogen generator

Coconut Mat for nitrogen generator

The measurement of preventing carbon molecular sieve from powdering in the nitrogen generator

The measurement of preventing carbon molecular sieve from powdering in the nitrogen generator

The production of nitrogen

The production of nitrogen